Meet Arianna Pandi

Meet Arianna Pandi

Can you please explain your job?

I work as a cleanliness and contamination control engineer in the exploration and science department at Thales Alenia Space’s Turin plant, where we design, manufacture, integrate and test spacecraft and modules for human and robotic missions. Contamination control applies throughout a spacecraft’s lifecycle, from its early design to launch, to avoid the unwanted accumulation of particles or organic matter that could degrade performance.

I’m currently working on several projects, ExoMars and Orion in particular. For science satellites or exploration missions, contamination control is obviously crucial. On ExoMars, for instance, led by Thales Alenia Space as prime contractor, the main objective is to look for signs of life, so one of the biggest challenges is to avoid any cross-contamination from humans that could lead to false positives and thus compromise scientific findings. Besides these amazing projects, I’ve also been supporting the Euclid mission to study dark matter. This is the next scientific satellite being built by Thales Alenia Space as prime contractor, to be launched in July this year.

© Thales Alenia Space

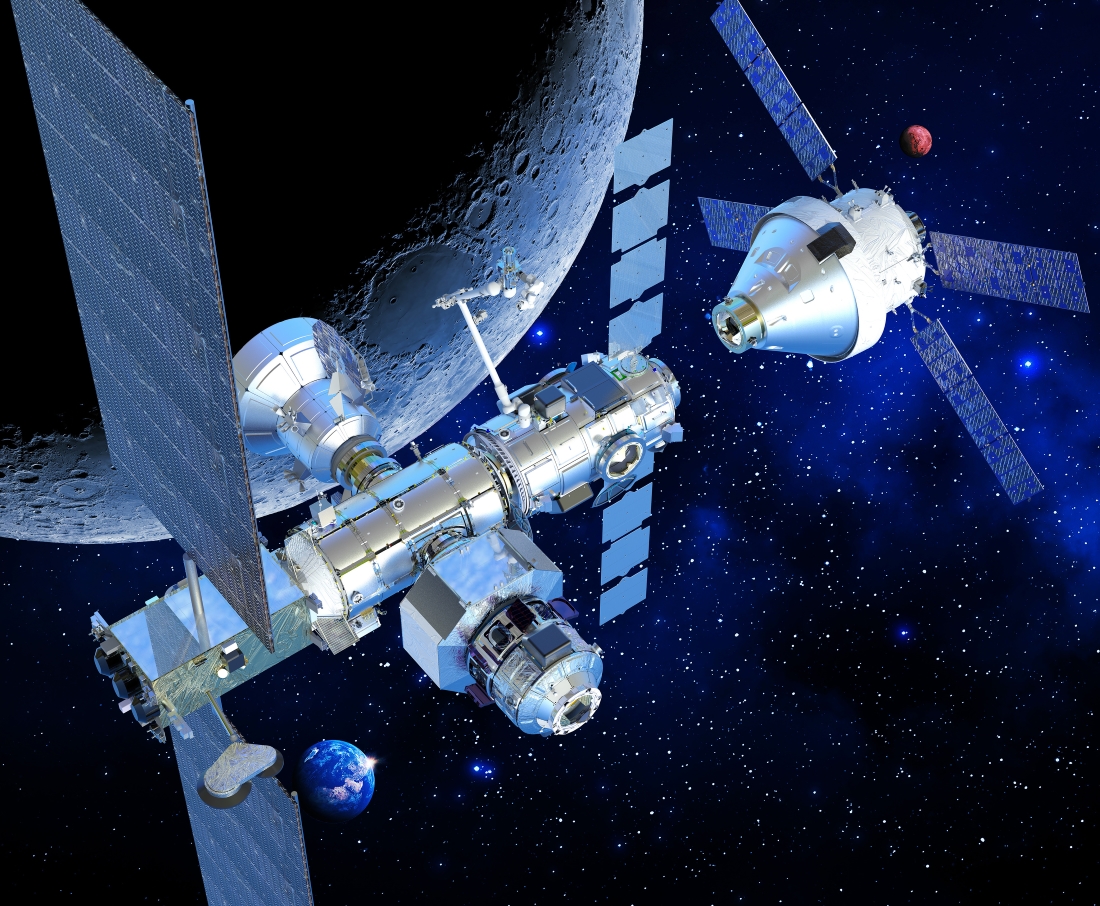

I’m proud to be working on human space exploration projects as well, especially the Lunar Gateway for the Artemis program. I’m involved in Orion’s European Service Module, for which we’re providing the thermal control and consumable storage and distribution subsystems, the first of which was successfully launched in 2022 with Artemis I. Today, we’re already working on model number 6! I’ve recently been involved as contamination control lead within the ESPRIT project, Thales Alenia Space’s main contribution to Gateway’s cislunar space station along with I-HAB and HALO. My job here is to guarantee that instruments are not only protected from contamination so they perform as expected once in space, but above all to protect astronauts’ health and work environment from contaminants and lunar dust.

I’m also involved in cleanliness and contamination control R&D activities for various exploration and science programs. The Turin plant has several units investigating new materials and technologies for all our products. This gives us the advantage of having a broad overview of the discipline, with the ability to conduct advanced tests in-house for all of Thales Alenia Space’s facilities and sectors.

What are you most proud of in your day-to-day activity?

Lunar Gateway © Thales Alenia Space

We develop world-class products and technologies that contribute to human space exploration and science.

We should never lose sight of our ultimate goal of bringing potential benefits to society at large – that’s how we stay motivated and continuously raise the bar. For example, given all the times I’ve analyzed parts of the ExoMars rover that will search for life on Mars, or all the tests done on the Orion water storage and distribution system for astronauts, I can already see how the development of a technology or the importance of a discovery can impact our future.

Which event in your career have you enjoyed the most?

Most of my best memories are from the integration and testing of satellites – the culmination of all the work done on design, calculations and models over the years: it’s a unique experience!

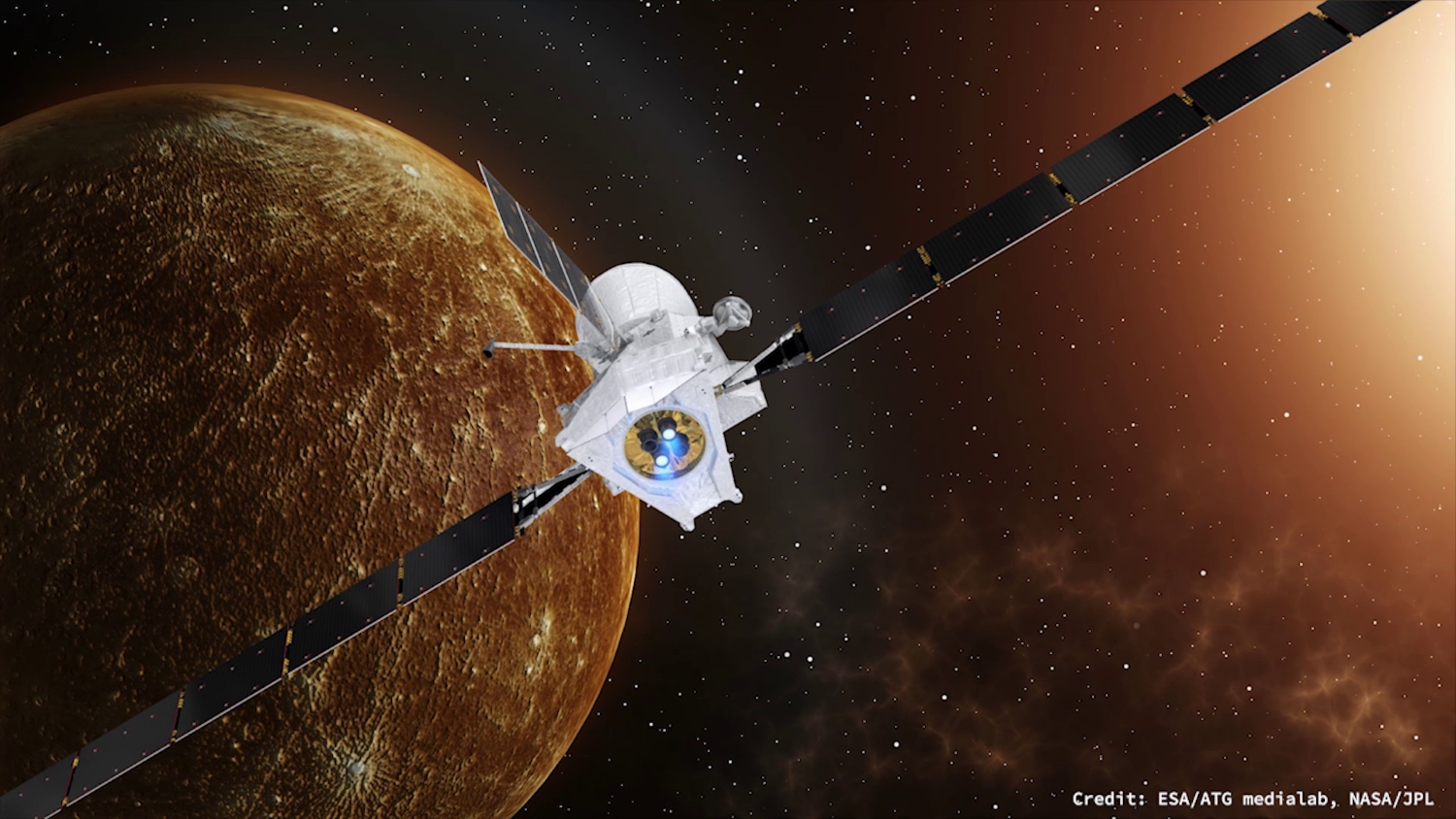

For example, my first ground contamination control activity was during Assembly, Integration and Testing activities for BepiColombo, and it was also my first experience as a contamination control support engineer. Working closely with colleagues from different disciplines, and in the constant presence of the customer, helped me not only expand my technical knowledge enormously in a short time, but also learn how to assess needs while fostering positive international collaboration.

Another experience that really helped me grow in my role was the ExoMars rover bake-out test in Thales Alenia Space’s thermal vacuum chamber in Rome. I was in charge of the overall technical organization, and seeing a whole team working together to reduce self-contamination from the rover was a tremendous source of pride.

Watching BepiColombo assembled for the vibration test or the rover inside the thermal-vacuum chamber made me think: this is why we do what we do!

In three words, what are the qualities required in your job?

I would say three words that are also the names of NASA Mars rovers. I’m confident that our European rover bearing the name of Rosalind Franklin – a chemist like me! – who helped unravel the double helix structure of DNA, will clearly embody the meaning of these three words.

Curiosity, because this must be what drives us to innovate, improve, and advance knowledge. Our skills and expertise are key to meeting our goals.

Perseverance, as our projects are challenging in so many ways and they take years to accomplish. We need to adapt to different situations without ever losing sight of the final goal, maintaining the same commitment when problems arise.

Team spirit: the ability to work as a team is obviously crucial. Everyone must contribute to the project, so sharing information and ideas and providing mutual support is the key to success.