SMS: advanced composite sandwich structures for tomorrow’s satellites

SMS at a glance

The aim of this study is to develop cutting-edge technologies that could be used to make lighter and stronger composite sandwich structures offering the same stability as with other materials – and all at an industrial scale. The plan is to use carbon-fiber reinforced plastics (CFRP) to form the honeycomb core of the sandwich. The composite panel “skins” could also be made of composites, or perhaps other materials, depending on the actual application. Along with these skins and the honeycomb core, other new technologies will be developed (calling on new bonding techniques in particular) to save weight and increase stability. One of the innovative solutions already chosen is a new bonding technique, using new materials and processes, that is designed to limit the influence of the adhesive between the core and the outer composite panels. More info: click here

Key benefits

The main advantage of the SMS project is that it would result in single-piece structures providing a host of benefits for satellite manufacturers. First, one-piece (integral) composite sandwich structures are more stable, meaning they stand up better to temperature fluctuations. In other words, they are less subject to the stress of expansion. The use of composite materials also means that they are lighter than conventional single-piece structures. Furthermore, the composite honeycomb core strengthens the overall sandwich structure more efficiently, giving the manufacturer greater leeway in terms of design and mechanical properties. Lighter, more stable and more flexible, composite structures will significantly improve the competitiveness of tomorrow’s satellites, thus inspiring an unprecedented technological advance for European observation systems.

In addition to these new production techniques, the project takes into account various logistics aspects, including procurement in Europe. The study kicked off in January 2016 and will finish at the end of 2017, leading to the design of a 1/6 scale prototype. This model will incorporate the technologies chosen, especially the composite honeycomb core and an appropriate assembly method. The prototype will subsequently undergo various demonstration tests, designed to prove its viability.

Partners

Thales Alenia Space and the Horizon 2020 program

This project has received funding from the European Union’s Horizon 2020 Research & Innovation program, under grant agreement No. 687548.

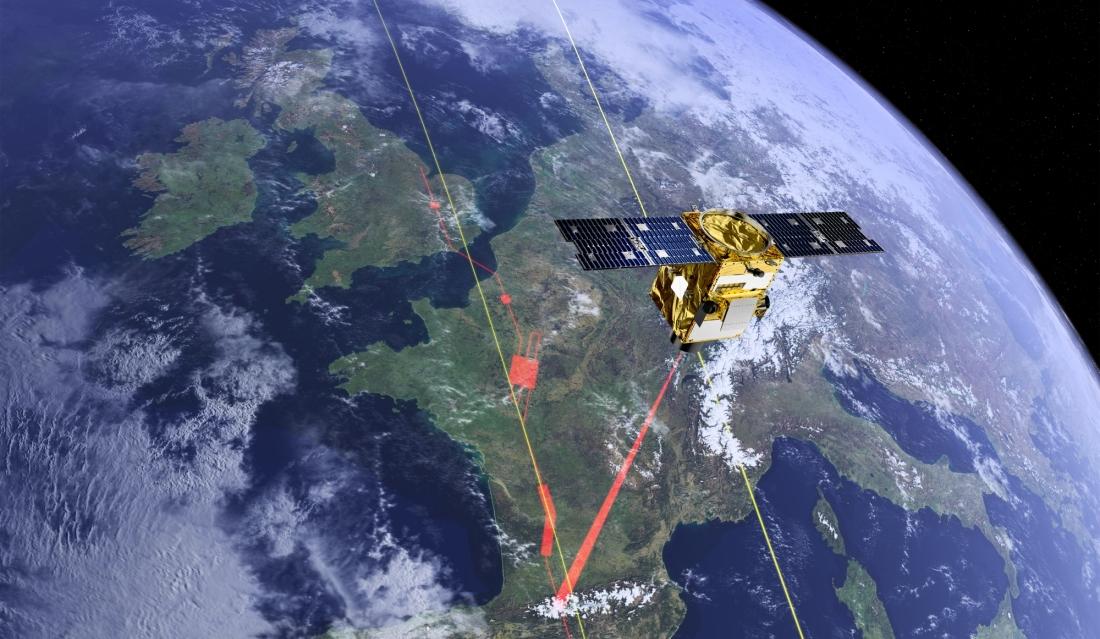

Copyrights: logo © SMS consortium - Artistic view © Thales Alenia Space/Master Image Programmmes